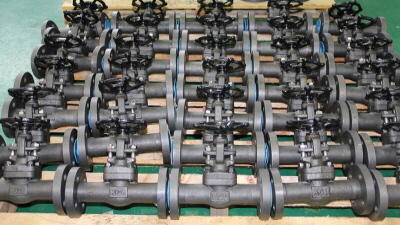

FORGED BALL / GGC VALVE

1. DESIGN

Floating Ball Valves are manufactured in the main type ;

One piece End Entry Type.

Three piece Bolted Construction.

Valves can be supplied Full or Reduced Bore and manufactured in forged construction.

Bolted and Screwed Body connections give convenience of service and maintenance on site.

Valves can be supplied with either Raised Face, Ring Type Joint, Socket weld or Screwed End

Connections, Pressure rating is from ANSI 150 thru ANSI 2500.

Higher pressures can be supplied on request. Valves are supplied with Lever.

2. MATERIAL SELECTION

Valves are manufactured in a range of materials such as Carbon steel, Low Temp Carbon steel,

Stainless steel, Duplex, Super Duplex, Monel, Titanium, Inconel and other Special Alloy.

3. BODY/CONNECTOR SEAL

Graphite ring, O-ring or PTFE seals guarantee perfect sealing between Body and Connector.

The Graphite ring continues to provide a seal in case of fire. O-ring can be supplied suitable for AED application

4. SEAT

Valve’s seat design gives perfect seal with various materials in both and low pressure application.

5. STEM

Stems are manufactured separately from the Ball and incorporate O-ring, Graphite ring, RTFE ring

and Anti-Static devices.

6.1 O-RING SEAT-RING Renewal Method

2-PIECED Body Ball valve

a. Break end connector loose with wrench.

b. Disassemble the body and the connector

c. Disassemble o-ring, seat-ring, ball and seat ring in order.

d. Place new o-ring and seat ring and then reassemble.

e. Assemble the body and the connector.

f. Tighten end connector into body.

g. Test according to regulated pressure.

3-PIECED Body Ball valve

a. Remove three pairs of bolts with the exception of one pair which remain in position but loosened. Turn and separate body from connector.

b. Remove the body seals, seat-rings

c. Clean the contact area of body and connector and place new seas and seat-rings.

d. Turn the body the other way and tighten connector bolts to reassemble at this point.

e. Test according to regulated pressure.

6.2 GLAND PACKING Renewal Method

a. Disassemble stem Nut, Name Plate, Lever, Stop Pin, and Disc Spring, Gland in order and then remove Gland Packing

b. Clean the parts and install new Gland Packing.

c. Reassemble the parts

d. Turn the Lever and check the operating condition.

e. Test according to regulated pressure.